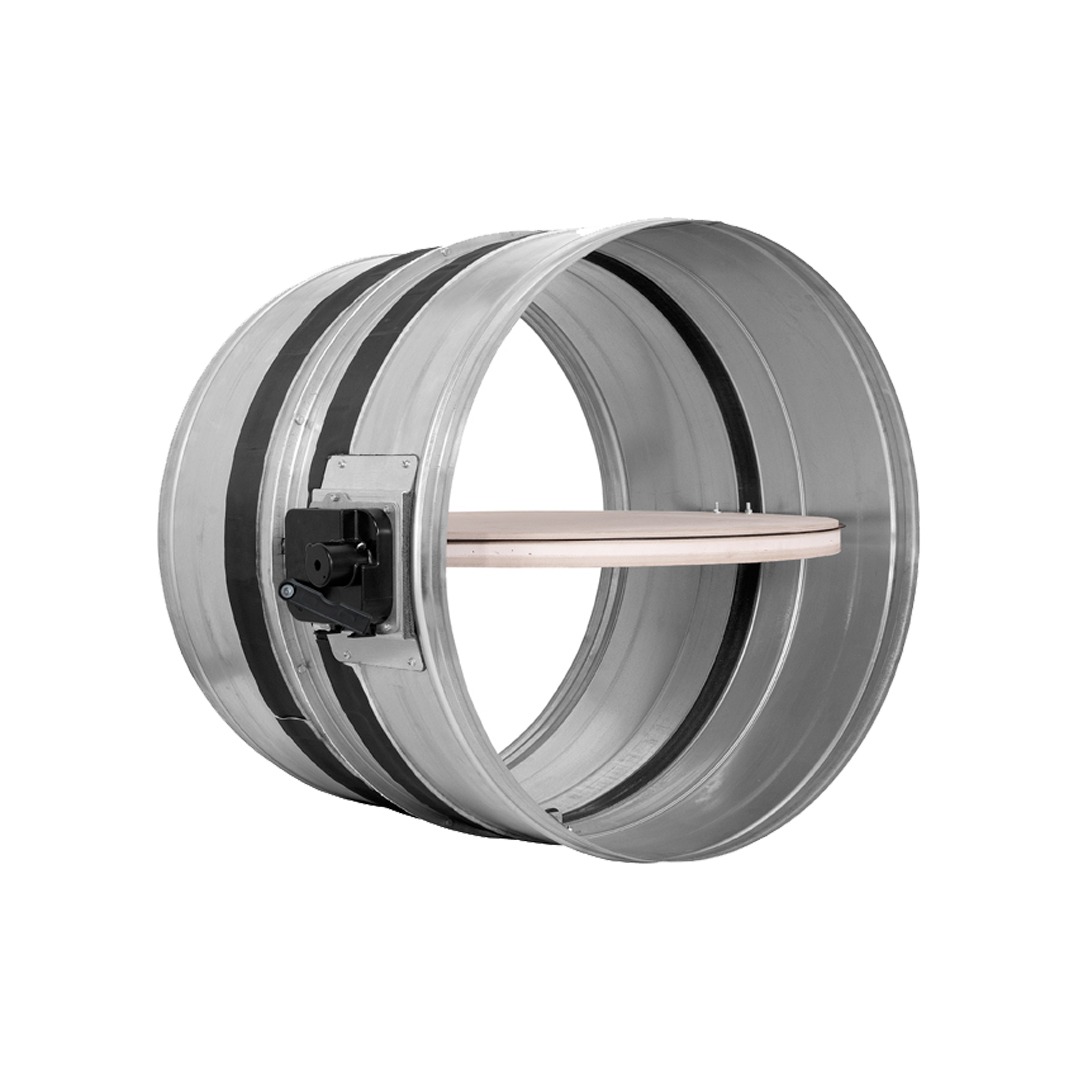

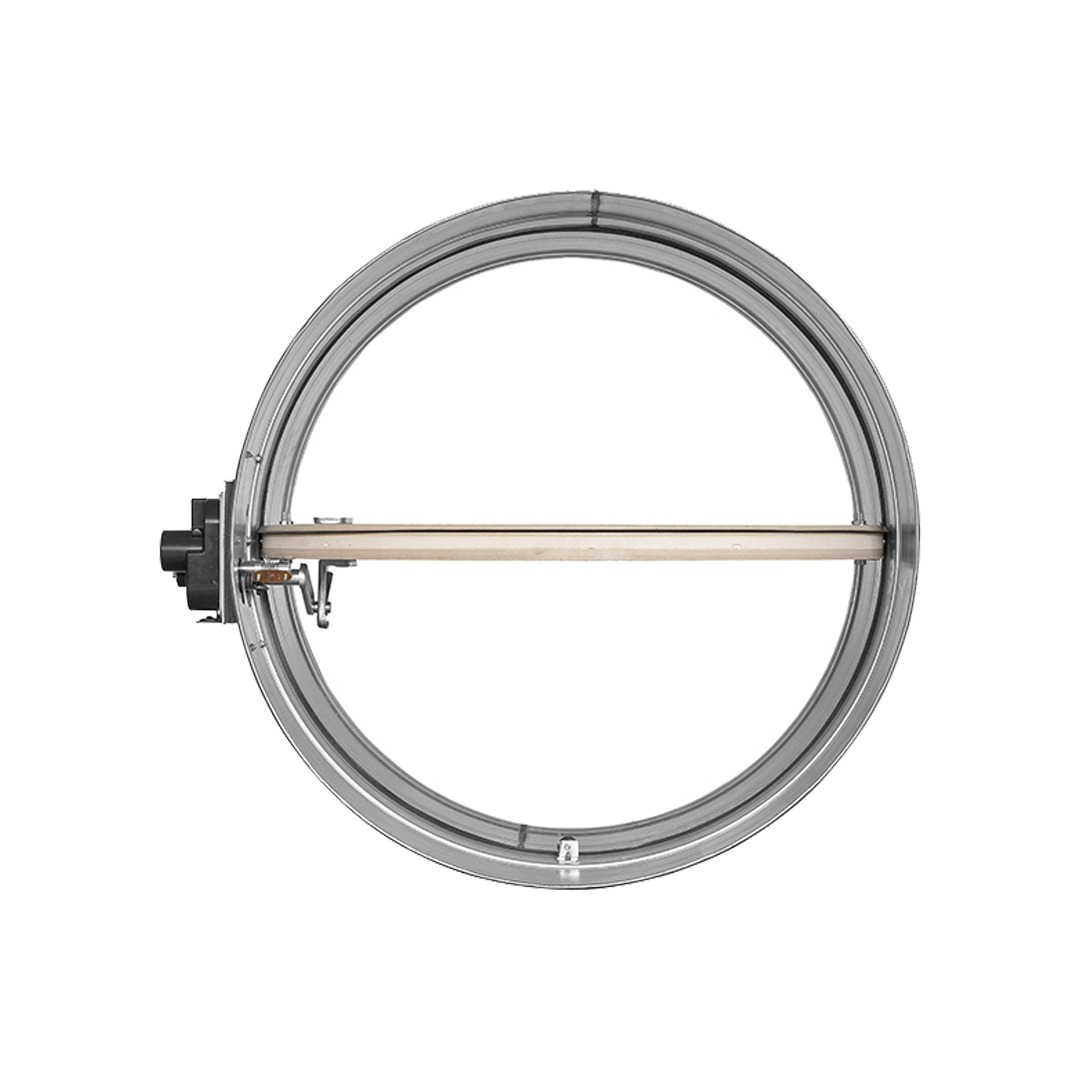

The WH45P series fire dampers, suitable for circular ducts up to diameter 800mm, allow maximum security in the prevention of spread of fire in buildings. They guarantee a perfect heat insulation and seal from hot and cold smoke as demonstrated by the various tests carried out in accordance with standard EN 1366-2.

They constitute a barrier from the spread of fire, transfer of heat and spread of harmful fumes and gases because of the use of the seal tested at 500Pa depression, much higher than the minimum required 300Pa as foreseen by standard EN 1366-2. By connecting them to fire and smoke alarm systems, it is possible to anticipate the closing of the damper blade before it comes into direct contact with the flame therefore preventing the onset of indirect damages that may result from the spread of fumes generated by combustion.

Technical data

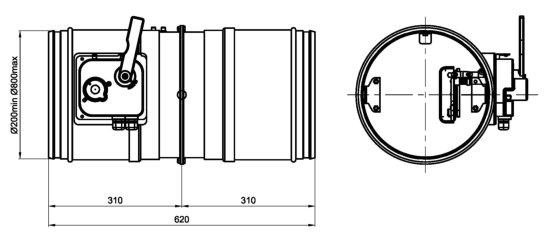

- Diameter range from 200mm up to 800mm.

- Casing made of galvanized carbon steel.

- Classified for installation:

- within rigid walls with fire class up to EI 120 (ve i↔o) S;

- within floors with fire class up to EI 180 (ho i↔o) S;

- within plasterboard walls with fire class up to EI 120 (ve i↔o) S;

- within gypsum blocks walls with fire class up to EI 120 (ve i↔o) S;

- transfer, without duct connection on one or both sides;

- for details of the fire resistance classes in function of the type of support and sealing, it is recommended to always refer to the technical manual and the Declaration of Performance.

- Installation flexibility:

- installable with any axis direction;

- minimum distance of 50mm between two fire dampers in the same wall or floor;

- Fire behaviour:

- automatic closure in less than 30 seconds when reaching 70 °C;

- insulation to heat and flame;

- indifferent to direction of origin of the fire;

- no thermal bridge between the two wall faces;

- no thermal bridge between the upstream and downstream ducts.

- Smoke behaviour:

- acts as smoke damper both in the absence of fire (cold smoke) and in the presence of fire (hot smoke) tested at 500Pa.

- Case tightness:

- class C according to EN 1751, for diameters greater than315mm, with positive and negative pressure up to 2000Pa.

- Corrosive environments:

- salt spray exposure test performed in accordance with EN 60068-2-52 overcome with degree of severity 2.

- Controls: mechanical, magnetic or motorized.

- Thermalfuse calibrated at 70 °C or 95 °C.